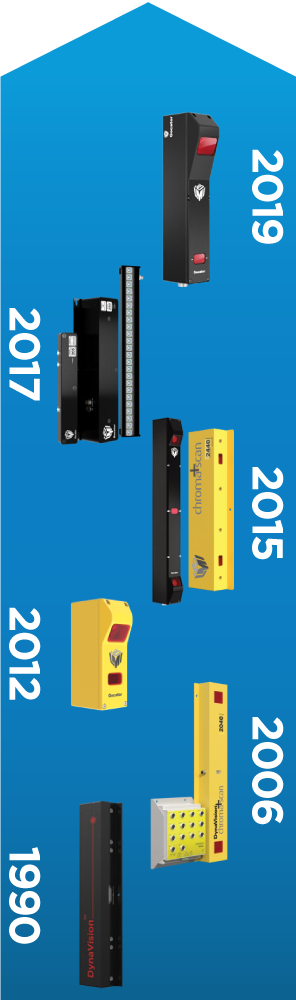

LMI’s service in the wood industry began with the release of the DynaVision brand for transverse board scanning in the early 1990s for maximizing volume recovery. The original M6 analog sensor featured 6 points covering a 2 foot board length and proved to be highly successful in saw mills across North America.

In the late 1990s, LMI released the DynaVision M24 and began supporting log scanning applications with the L4. The M24 multi-point sensor offered the highest density ever released at 23 points. The L4 offered a snapshot design using 4 laser lines with 12” spacing between lasers and 1” resolution at 300’ (91m) per minute to scan logs on a headrig carriage. In early 2000, LMI introduced the B800 with 8 points to address the need for a low-density, low cost board scanning solution.

2007 marked the birth of a new product line from LMI––chroma+scan. Designed for maximum value recovery in lineal and transverse log and board scanning, chroma+scan entered the market with a ground-breaking 76 points and 1mm color resolution. In 2009, tracheid detection was introduced to chroma+scan’s technology. Combining profiling, vision, and tracheid scanning enabled chroma+scan sensors to determine wood quality by detecting features such as grain angle, sound vs. unsound fiber, and blond knots.

In 2012, LMI introduced the Gocator 3D Smart Sensor for general wood scanning applications, with a primary focus on log scanning. Unlike previous generations, Gocator does all the heavy lifting onboard the sensor (scanning, measurement, and PLC control) and is easily set up through a web browser. Gocator promises to revolutionize the wood industry with its FactorySmart® features and all-in-one design that open up applications everywhere in the mill including optimization, machine control and machine monitoring.

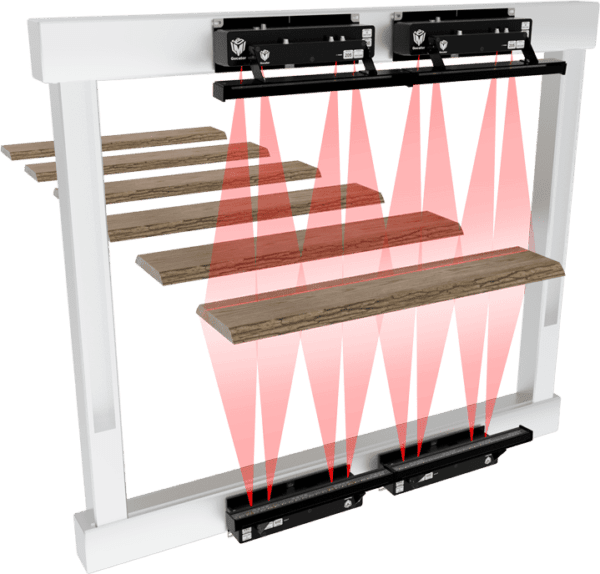

In 2017 we introduced the Gocator® 200 Series, a dedicated smart sensor product line that provides a new level of flexibility and functionality in wood scanning applications. This sensor lineup brings exciting new opportunities for optimizing wood in both saw and planer mills. By combining the success of our patented chroma+scan technology with our industry-leading Gocator® platform, LMI has created a highly configurable, easy-to-use solution for transverse board scanning.

Based on the proven high density profile design of chroma+scan, Gocator 200 scanners run 50% faster to achieve scan rates at 3 kHz. In addition, tracheid scan rates are 3x faster to deliver 1.5 kHz density for exceptional detail in wood grain detection.

In 2017 we introduced the Gocator® 200 Series, a dedicated smart sensor product line that provides a new level of flexibility and functionality in wood scanning applications. This sensor lineup brings exciting new opportunities for optimizing wood in both saw and planer mills. By combining the success of our patented chroma+scan technology with our industry-leading Gocator® platform, LMI has created a highly configurable, easy-to-use solution for transverse board scanning.

Based on the proven high density profile design of chroma+scan, Gocator 200 scanners run 50% faster to achieve scan rates up to 4 kHz. In addition, tracheid scan rates are 3x faster to deliver up to 2 kHz density for exceptional detail in wood grain detection.

Fill out the form on the right to have our Sales Representative reach out to you.

© 2024 LMI TECHNOLOGIES INC. ALL RIGHTS RESERVED.